Most Popular

-

Vibration Analysis: The Key to Predictive Maintenance

Predictive maintenance offers a powerful toolbox, and vibration analysis is a cornerstone. It excels.. -

See it Before it Breaks: Non-Destructive Testing for Predictive Maintenance

Non-Destructive Testing (NDT) helps factories see inside machines to find hidden flaws, preventing c.. -

Beyond the Basics: Advanced NDT Techniques for Cutting-Edge Predictive Maintenance

This article explores cutting-edge NDT techniques like infrared thermography and acoustic emission t.. -

Don't Wait for Disaster: How Oil Analysis Saves You Money and Equipment?

Oil analysis is a preventive maintenance technique that analyzes oil to predict machine problems and.. -

Power Up Your Reliability: The Essential Role of Vibration Analysis in Wind Energy

Wind turbine vibrations reveal machine health. Analysis helps predict problems early, reducing downt.. -

From Reactive to Proactive: Oil Analysis - Your Weapon Against Downtime

Oil analysis is a powerful tool for the oil & gas industry. By analyzing lubricating oil, companies ..

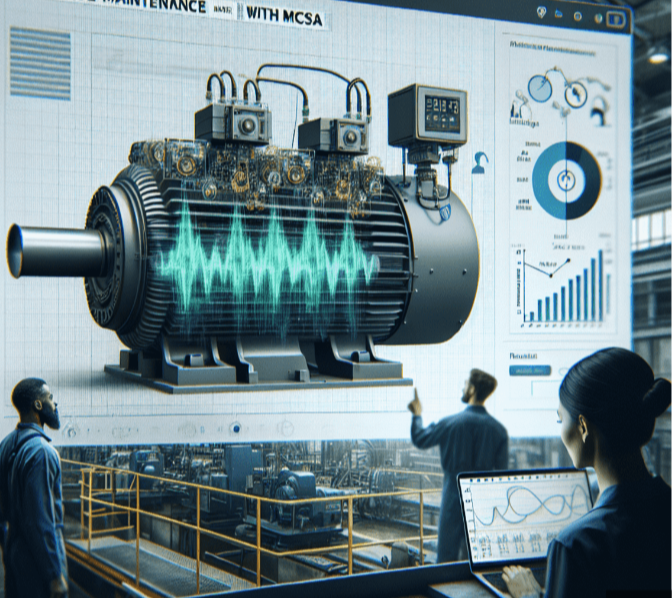

One of the best predictive maintenance techniques for determining the health of industrial machinery is Motor Current Signature Analysis (MCSA). Through early problem detection, MCSA enables proactive maintenance, in contrast to traditional diagnostics, by analyzing current data from asynchronous motors. By preventing possible problems before they arise, reducing downtime, and improving operational efficiency, it seeks to maximize equipment performance.

MCSA is excellent at identifying problems early on and gives maintenance personnel a thorough grasp of the condition of the machinery through careful motor current signal analysis. Production disruptions are avoided by this proactive capability, which is vital in sectors of the economy where there are high financial and safety concerns. Its meticulous methodology entails obtaining current data, utilizing spectral analysis—often with FFT—and specialized equipment for precise recording. This methodical procedure guarantees in-depth evaluations of the health of the machinery, resolving problems in their entirety and reducing oversight.

From stator winding irregularities to rotor imbalances, MCSA's accuracy and adaptability in problem solving cover coupling problems, load irregularities, efficiency subtleties, and even bearing glitches. With the help of this all-encompassing approach, maintenance teams can plan strategically and make targeted interventions because they have a thorough awareness of the health of the gear. Including MCSA in maintenance procedures encourages proactive approaches by offering intervention roadmaps and early alerts to maximize equipment performance, reduce downtime, and improve operational effectiveness. Its capacity to distinguish between diverse issues sorts effectively prioritizes maintenance tasks, cutting expenses and enhancing equipment dependability.

MCSA- Provide a Transformative advantage of Predictive Maintenance Motor Current Signature Analysis (MCSA) offers a transformative advantage in predictive maintenance, providing unparalleled insights into machinery health and enabling proactive interventions. These advantages are:

- Early Detection of Issues

- Enhanced Equipment Reliability

- Improved Safety

- Cost savings by minimizing downtime and reducing the need for emergency repairs

- Increased Equipment Uptime