Transforming Paper Mill Maintenance With Reliability-centered Maintenance (rcm)

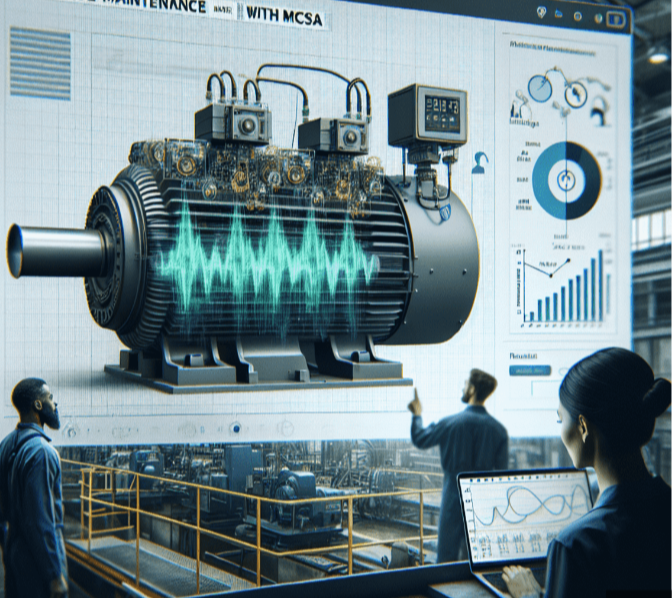

Explore how Reliability-Centered Maintenance (RCM) revolutionizes paper manufacturing, driving efficiency, reliability, and competitive advantage through proactive maintenance strategies and continuous improvement processes.

Revolutionizing Maintenance Strategies Across Industries: The Power Of Reliability Centered Maintenance (rcm)

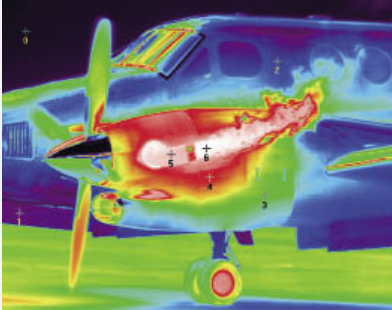

Reliability-Centered Maintenance (RCM) is a systematic approach to optimize maintenance programs by identifying potential problems and implementing proactive measures to enhance equipment reliability while minimizing costs.